As an Amazon FBA seller, you know that time is of the essence. The quicker Amazon processes your products in their fulfillment centers, the quicker they can sell and ship out to customers.

As we’ve seen throughout the last few years of the pandemic, Amazon processing times have fluctuated, and receiving times are slower than normal. For many sellers, this has caused FBA shipments to appear in receiving status for quite some time, which not only affects sales and stock levels, but impacts your inventory forecasting and FBA inventory send-in dates.

We know firsthand how frustrating it is to see shipments that are still in a receiving status. The SupplyKick team has broken down why this happens and what brands leveraging FBA can do about it—including a few inventory management techniques you can use to avoid delays with Amazon in the future.

If you’re using FBA as your Amazon fulfillment solution, you may notice that certain shipments appear in “receiving” status for longer (or much longer) than expected. This may mean one of two things:

Generally, Q4 is a consistently slow quarter for receiving times due to the busy holiday shopping season, but at any time throughout the year, an Amazon FC can become inundated and experience delays. Throw in a global supply chain crisis, and ongoing FBA storage restrictions, and delays may happen more often than usual.

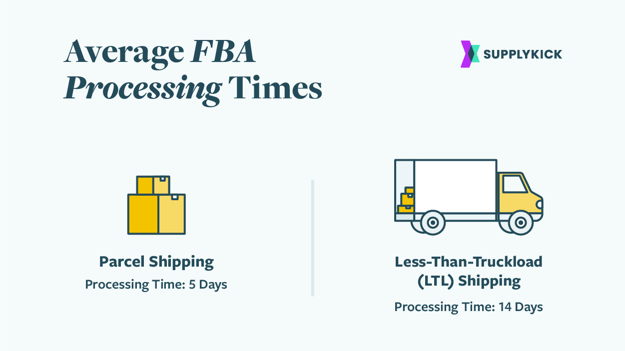

For any shipment method, outliers can occur and shipments may take longer to receive by Amazon at any time. However, we’ve found that our parcel shipments are typically received and processed a lot faster than LTL shipments—nearly three times faster.

Here are the average FBA processing days SupplyKick sees based on shipping method:

With that said, while the process is out of your hands (literally and figuratively) once you ship to Amazon, creating smaller shipments may help your transit and receiving times. If you’re shipping LTL and experiencing issues or delays, it may be a good idea to switch over to parcel shipments for a short time —as long as your shipment meets Amazon’s parcel requirements and you can absorb the potential additional shipping costs—to speed up the stock-in process.

Proper packaging is the best way to avoid any hiccups in Amazon’s receiving process. Small oversights here can lead to significant delays. If your shipment has been marked as received but hasn’t been stowed, chances are it’s being looked into by an Amazon employee—and your product will take longer to hit the shelves.

While your shipment method is the biggest key to processing times, you should also follow these best practices to keep the fulfillment process as smooth as possible:

For more info on all things Amazon fulfillment, take a look at this guide made by Amazon for sellers like you. Speaking of guides, our FBA holiday calendar lists the most important consumer shopping dates and holidays this year so you can stay on top of trends and hone your shipping strategy.

Need help with Amazon fulfillment, inventory forecasting, or other FBA strategies? Connect with our team.

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Sign up to receive our newsletter for growth strategies, important updates, inventory and policy changes, and best practices.

These Stories on Logistics & Fulfillment

For press inquiries, please contact Molly Horstmann, mhorstmann@supplykick.com